Tsena ke lintlha tse 3 bakeng sa hlobo ea mocheso o phahameng o nang le resin ea PPSU

Melemo ea thepa ea PPSU ke efe?

Ho hanyetsa mocheso oa nako e khutšoanyane oa polasetiki ea PPSU e phahametse likhato tse 220, 'me mocheso oa nako e telele o ka fihla likhato tse 180,' me o ka mamella mocheso oa mocheso oa oli oa likhato tse 170-180.Likarolo tsa PPSU li na le botsitso bo botle ba sebopeho, 'me li khona ho mamella metsi a chesang / sehatsetsing / oli ea mafura.Ka thepa ena e ntle haholo, PPSU e ka sebelisoa ho hlahisa lihlahisoa tsa boleng bo holimo tsa tekheniki le tse boima haholo.Hona joale e fetoha thepa ea pele ea ho nkela tšepe sebaka, li-ceramics le li-polymer tse thata.

Li-plastiki tsa PPSU li ntse li sebelisoa haholo ho lokiseng le ho futhumatsa lijo tse chesang, haholo-holo bakeng sa likaroloana tse phahameng tsa motlakase tse tlamehang ho ba le botsitso bo phahameng ba boemo bo phahameng le thepa e ntle ea ho kenya motlakase le lisebelisoa tse ntle tsa motlakase hammoho le ho hanyetsa botsofali bo phahameng, ho hanyetsa mollo o matla, le ho hanyetsa ho hoholo ha lik'hemik'hale. le hydrolysis.

Ka sena, e fetoha sesebelisoa sa bohlokoa lits'ebetsong tse fapaneng tse fapaneng liindastering tse kang sefofane, lisebelisoa tsa motlakase le tsa elektroniki, likoloi le lipalangoang.

U ka etsa taolo ea mocheso joang bakeng sa ho bopa ha PPSU?

Joalo ka li-thermoplastics tse ling tsa boenjiniere, tlhahiso e tsitsitseng ea likarolo tse bōpiloeng tsa boleng bo holimo e hloka taolo e nepahetseng ea mocheso oa hlobo ea ente ea mocheso o phahameng.Ka bobeli metsi le oli li khona ho laola mocheso oa hlobo o pakeng tsa 140 le 190 degrees.Haeba thepa ea ho laola mocheso e entsoe hantle, metsi a ka bang likhato tse 200 a ka sebelisoa e le mecha ea phatlalatso ea ho laola mocheso.Taolo ea mocheso oa elektronike e ka boela ea sebelisoa maemong a itseng.Pele o etsoa ka ente, thepa ea PPSU e lokela ho omisoa, re khothaletsa ho omisa thepa ka mocheso oa likhato tse 150-160 bakeng sa lihora tse 3-6.Moqomo oa mochini oa ho etsa ente o lokela ho hloekisoa ka ho lekaneng.'Me mocheso oa ente o khothalletsoa hore o laoloe ho pota 360-390 likhato.

Mokhoa oa ho etsa liforomo tsa ente ea mocheso o phahameng bakeng sa thepa ea PPSU?

Mofuta oa ente oa thepa ea PPSU o tlameha ho khona ho mamella mocheso o batlang o le holimo joalo ka sesebelisoa sa ho bopa mocheso o phahameng.Ntle le ho amohela moralo o nepahetseng oa mochini le ho khetha thepa e nepahetseng ea hlobo, liphaepe tse sa keneng mocheso le khatello le tsona li lokela ho sebelisoa ho ntlafatsa moralo oa likanale tse futhumatsang, litiiso le likhokahanyo.

Lintlha tsa Moralo:

1. Khetho le phekolo ea tšepe: a).Mocheso oa hlobo o lokela ho thehoa ho likhato tse 140 ho isa ho tse 150, 'me bophelo ba hlobo bo lokela ho nkoa ka tlhahiso ea bongata.b).Phekolo ea mocheso oa hlobo e hlokahala hore e be HRC60-65 ka kakaretso.c).Kalafo ea electroplating e ka eketsa bophelo ba tšebeletso ea ho bopa.

2. Sebopeho sa semathi: ho pota-pota kapa trapezoid e loketse.Ho boetse ho hlokahala seliba se batang sa slug.

3. Mefuta ea liheke: Heke ea ntlha ea phini, heke ea li-tab, heke ea disk, heke e buuoang, heke e ka thōko, heke e tobileng le heke e nyenyane.

4. Phallo ea Khase: Ho kenya moea ho bohlokoa haholo bakeng sa hlobo ea thepa ea PPSU.Ho kenya moea ha hoa lekana ho tla baka ho chesoa, ho fetoha ha mebala le sebaka se mahoashe joalo-joalo.Leqhubu la khase hangata le bolelele ba 0.015 ~ 0.2mm le bophara ba 2mm.

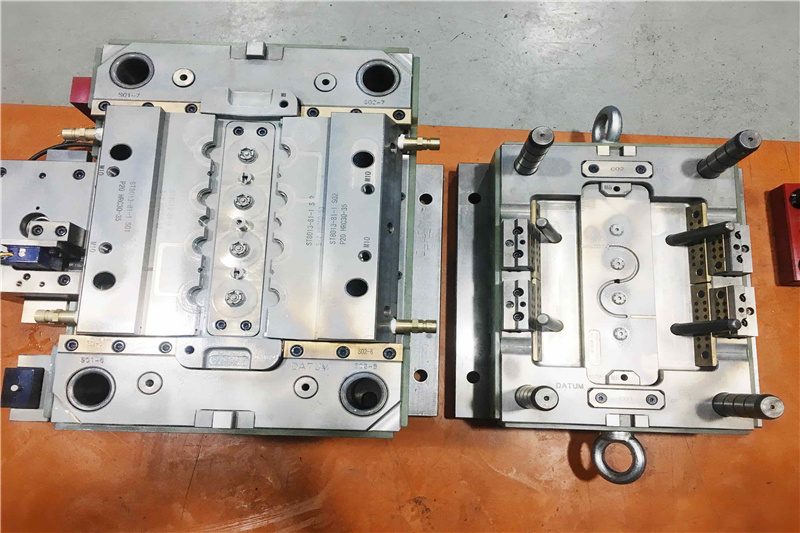

Suntime Precision Mold e na le boiphihlelo bo bongata ba ho etsa hlobo ea ente ea polasetiki bakeng sa hlobo e phahameng ea mocheso bakeng sa thepa e kang PPSU le PEEK.Bareki ba thabile haholo ka boleng ba rona ba boleng bo holimo le nako ea ho etella pele ka potlako.Ka tlase foto ke e 'ngoe ea hlobo e phahameng ea mocheso eo re e entseng bakeng sa likarolo tsa plumping & tse loketseng.Ke hlobo e 4 ea cavity e itokollang.Bakeng sa tlhaiso-leseling e batsi mabapi le mofuta ona oa hlobo, ka kopo sheba boithuto ba rona webosaeteng:https://www.suntimemould.com/auto-unscrewing-plastic-injection-mould-with-ppsu-material-high-temperature-mold-product/

Nako ea poso: Dec-18-2021