Aluminium die casting ke ts'ebetso eo ho eona motsoako oa aluminium o qhibilihisitsoeng o qobelloang ho etsa tšepe kapa hlobo tlas'a khatello.Hangata e sebelisoa bakeng sa tlhahiso ea bongata 'me e ka hlahisa likarolo tse nang le lintlha tse rarahaneng haholo hammoho le likarolo tse nang le mamello e thata haholo ka theko e tlaase haholo.Likarolo tse hlahisoang ho tloha ho aluminium die casting li na le thepa e ntle ea mochini mme li hanana le kutu, mocheso le ho khathala.

• Aluminium die casting e fana ka melemo e mengata, e meng ea eona e kenyelletsa:

• Lisebelisoa tse bobebe le tse matla tse nang le litšenyehelo tse ngata ho feta mefuta e meng ea tšepe

• Bokhoni bo ntlafetseng ka lebaka la nako e khutšoanyane ea ho etella pele le ho fokotsa litšila

• Keketseho ea tokoloho ea moralo ka lebaka la ho senyeha ha eona, ho lumella libopeho tse rarahaneng hore li thehoe kapele le ha bonolo

• Ho hanyetsa ho hoholo ha kutu, mocheso le ho senyeha ha ho bapisoa le litšepe tse ling

• Bokhoni ba tlhahiso ea bongata, ka li-alloys tse ngata tsa aluminium tse khonang ho mamella khatello e phahameng le mocheso

Aluminium die casting ke mokhoa o makatsang oa tlhahiso o sebelisoang ho hlahisa likarolo tse fapaneng tsa liindasteri tse fapaneng.Ho tloha ho likarolo tsa koloi ho ea ho li-implants tsa bongaka le tse ling, aluminium die casting e ka sebelisoa ho theha hoo e batlang e le eng kapa eng, joalo ka:

• Indasteri ea likoloi:Likarolo tse fapaneng tse kenyelletsang trim ea kahare, li-casings tsa phetisetso, li-block tsa enjine le li-mountings, li-radiator le lisebelisoa tsa ho tjhaja.

• Indasteri ea sepakapaka:Likarolo tse rarahaneng tse kang lipompo, lisensara, li-actuator, litora tsa seea-le-moea le manakana.

• Indasteri ea bongaka:Likarolo tse ikhethang tse kang li-valve tsa pelo tse kentsoeng, lisebelisoa tsa ho buoa, li-orthotics le li-prosthetics.

• Lisebelisoa tsa lapeng:Lihinge le lilache tsa lihatsetsi le mechini ea ho hlatsoa liaparo hammoho le likaroloana tse ling tse nyane tse hlokang mosebetsi o rarahaneng.

• joalo-joalo,.

Ho khetha motsoako o nepahetseng oa aluminium bakeng sa projeke ea hau ea "die casting" ho bohlokoa ho netefatsa hore sehlahisoa sa hau se felileng se kopana le litlhaloso tsohle tsa hau.Malebela ke ana a ho khetha alloy e nepahetseng:

• Nahana ka litlhoko tsa matla le ho tšoarella ha karolo ea hau.Li-alloys tse fapaneng li fana ka maemo a sa tšoaneng a matla le ho hanyetsa, kahoo ho bohlokoa ho khetha motsoako o tla finyella litlhoko tsa kopo ea hau.

• Hlahloba boemo bo hlokehang ba ho hanyetsa ho bola.Li-alloys tsa aluminium li ka phekoloa le ho kenngoa ka anodized ho fana ka tšireletso e eketsehileng khahlanong le ho bola, kahoo etsa bonnete ba hore u nahana hore na likarolo tsa hau li tla hloka ho mamella tikoloho efe.

• Nahana ka litšenyehelo tsa tlhahiso le linako tsa ho fana.Ho ipapisitse le ho rarahana ha karolo, li-alloys tse fapaneng li ka hloka mekhoa e fapaneng ea tlhahiso kapa matsete a lisebelisoa, kahoo ho bohlokoa ho lekanya lintlha tsena ha u khetha motsoako oa morero oa hau.

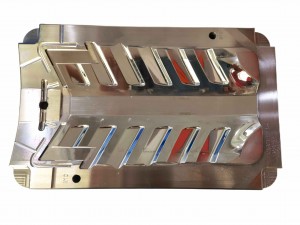

Lisebelisoa le litlhoko tsa machining bakeng sa aluminium die casting li fapana ho latela motsoako o sebelisitsoeng, ho rarahana ha karolo, le lintlha tse ling.Ka kakaretso, ha u khetha mofuta oa sesebelisoa, ho bohlokoa ho nahana ka lintlha tse latelang:

• Khetho ea thepa ea lisebelisoa e lokela ho thehoa holim'a motsoako o sebelisoang le mocheso o hlokahalang bakeng sa ho hlahisa liphello tsa boleng.Ka tloaelo re sebelisa H13, SKD61, 8407, 8418, 8433 le W360 bakeng sa lisebelisoa tsa die cast.

• Tlhokomelo e tlameha ho nkuoa ho etsa bonnete ba hore ho na le li-angle tse lekaneng tse etsang hore likaroloana li khone ho tloha ho letoto ha li ntšoa.Tlhahlobo e felletseng ea DFM e lokela ho etsoa pele ho moralo oa hlobo.

• Mechine ea bobeli e ka 'na ea hlokoa ka mor'a ho lahla e le hore u finyelle libopeho kapa lintlha tse itseng, e kenyelletsa machining a CNC, ho cheka, ho tlanya joalo-joalo.

• Likhetho tsa ho Qetella ka holim'a metsi tse kang ho phatloha lehlabathe kapa ho bentša ka vibratory, anodizing, plating kapa ho penta le tsona li ka hlokahala ho latela litlhoko tsa hau.

CNC Machining bakeng sa Die Casted Parts

Ho rarolla mathata a tloaelehileng ho aluminium die castings e ka ba ts'ebetso e jang nako le e theko e boima, empa ho bohlokoa ho netefatsa boleng ba likarolo tsa hau.Malebela ke ana a ho rarolla mathata a tloaelehileng ka li-castings tsa aluminium:

• Porosity:Hlahloba karolo ea hau bakeng sa li-pinholes kapa libaka tse ling tse ka lebisang ho porosity.Haeba u fumana leha e le efe, etsa bonnete ba hore u hlahloba mocheso oa hlobo, khatello ea ente le lintlha tse ling tse ka 'nang tsa ama ho tlatsoa ha sengoathoana.

• Phetolo:Haeba u fumana ho khopama likarolong ka mor'a hore li tlosoe lefung, hlahloba ho bona hore na moralo oa hlobo kapa linako tse pholileng li ka 'na tsa baka bothata bona.U ka 'na ua hloka ho lokisa litlhophiso tsena bakeng sa litsamaiso tsa tlhahiso ea nako e tlang ho fokotsa ho khopama hofe kapa hofe.

• Litšitiso:Haeba u kopana le bofokoli bofe kapa bofe bo kang splay marks kapa mapheoana, hlahloba hore na ho na le phapang pakeng tsa lebelo la ente le sekhahla sa phallo ea ho qhibiliha, kaha hangata sena se ka baka mathata ana.Ho ka 'na ha hlokahala hore ho lokisoe liparamente tsa ho lahlela tse kang mocheso le likhahla tsa ho pholisa e le ho fokotsa ho se phethahale ha bokaholimo.

Ha projeke e ncha e qala, likarolo tse potlakileng tsa prototyping lia hlokahala bakeng sa mefuta ea liteko.Ho na le mekhoa e mengata ea ho etsa li-prototypes tse kenyelletsang mochini oa CNC, Vacuum casting, khatiso ea 3D le sesebelisoa sa Rapid prototype.

• Mechine ea CNC e ka etsa likarolo tsa tšepe le tsa polasetiki ka bongata leha e le bofe.

• Vacuum Casting ke ea likarolo tsa polasetiki tsa 5-100 ka ho sebelisa hlobo ea silicon

• 3D Printing ke ho hatisa likarolo tsa ABS, PA kapa Steel.Bakeng sa polasetiki, likarolo tse hatisitsoeng tsa 3D ha li khone ho mamella mocheso o phahameng.

• Rapid prototype tooling ke hlobo e bonolo e entsoeng ka tšepe e bonolo joaloka S50C kapa Aluminium.Tharollo ena e ka hlahisa likarolo tse ngata ho feta Vacuum casting.Nako ea ho etella pele e khuts'oane ho feta lisebelisoa tsa tlhahiso mme theko le eona e tlase.

Lisebelisoa tseo re li sebelisitseng: Lipolasetiki tse kang PC, PMMA, POM, PP joalo-joalo.Metal joaloka tšepe, aluminium, koporo, koporo joalo-joalo.

Mokhoa oa ho etsa likarolo tsa silicon

Ho theha karolo ea silicone, o tla hloka ho sebelisa mokhoa oa ho etsa ente.Sena se kopanyelletsa ho qhibilihisa polasetiki ka mochine oa ente le ho e kenya mokoting o koetsoeng, moo e pholileng le ho thatafala ho nka sebopeho se lakatsehang.

Mekhoa e meng eo u ka e sebelisang e kenyelletsa ho etsa mochine oa khatiso, vacuum casting, kapa khatiso ea 3D.Mokhoa o mong le o mong o fana ka melemo le likotsi tse ikhethang ho latela hore na u leka ho theha karolo ea mofuta ofe.

Ka mekhoa eohle, ho fumana mocheso o nepahetseng le khatello ke senotlolo sa ho fihlela litekanyo tse nepahetseng le thepa ea thepa e lakatsehang.

Lisebelisoa tsa likarolo tsa silicon

Ho na le liindasteri tse ngata tse ka sebelisang likarolo tse bonolo tsa silicon joalo ka Likoloi, Bongaka, Electronic, houseware, kitchenware le tse ling tse ngata.Bakeng sa likarolo, hangata u ka fumana tsena tse kang Gaskets, Litiiso, O-rings, Air filters, Hoses, Lighting components, cellphones, likoahelo tsa Keyboard, Lithapo le lithapo tsa motlakase le lisebelisoa tse ngata tsa Bongaka.

Likarolo tsa setempe tsa tšepe ke likarolo tsa tšepe tse entsoeng ka mokhoa oa ho hatakela tšepe, mokhoa oa tlhahiso o kenyelletsang ho otla, ho seha kapa ho etsa lishiti tsa tšepe ka libopeho tse lakatsehang.

Metal stamping e sebelisoa ho theha likarolo bakeng sa liindasteri tse fapaneng tse fapaneng ho kenyeletsoa liindasteri tsa likoloi le tsa sefofane.

E ka boela ea sebelisoa ho etsa libopeho tse tloaelehileng le tse rarahaneng.Melemo ea ho sebelisa setempe sa tšepe e kenyelletsa ho boloka litšenyehelo, ho rarahana ha moralo le ho feto-fetoha ha maemo.

SPM e thusitse bareki ka thepa e ngata ea litempe tsa tšepe bakeng sa projeke ea bona ea turnkey, ts'ebeletso ea rona e sebetsang ea boenjiniere e ka boloka litšenyehelo le nako ea bona e ngata.

Li-jigs le li-fixtures ke lisebelisoa tse sebelisetsoang ho thusa ts'ebetsong ea ho etsa likarolo le likarolo tse fapaneng.

Jig ke sesebelisoa se ikhethileng se thusang ho tataisa, ho ts'oara, kapa ho beha karolo ea mosebetsi sebakeng sa eona nakong ea ts'ebetso e fapaneng ea machining, joalo ka ho cheka, ho sila le ho etsa sebopeho.

Lisebelisoa ke lisebelisoa tse khomaretsoeng mochining kapa bencheng ea mosebetsi mme li thusa ho fumana le ho boloka likarolo ha li ntse li sebetsoa.

Li ka ba tloaelo e etselitsoeng ho sebetsana le mesebetsi e sa tšoaneng ho netefatsa ho nepahala le ho sebetsa hantle.Li-jigs le lisebelisoa tse peli li ka etsoa ka tšepe tse kang tšepe kapa aluminium 'me li bohlokoa bakeng sa ho hlahisa likarolo tse nepahetseng ka boiteko bo fokolang.

SPM e etsa li-jigs le li-fixtures bakeng sa tlhahiso ea rona ea ho bopa ente hape e fana ka ts'ebeletso ea ho e etsetsa bareki.

Haeba u batla sena, ka kopo ikopanye le nako efe kapa efe.

FUMANA QUOTE HONA HONA JOALE!

-

Ente hlobo e ngata ea cavity bakeng sa likatiba tsa packa...

-

Plastic tooling family hlobo koloi mohatla lig...

-

CNC ho sila le ho fetola barekisi ba machining

-

Moetsi oa hlobo ea ente ea polasetiki, die castin ...

-

Tšebeletso ea ho bopa ka Ente ea Plastiki

-

Mofuta o nepahetseng oa ente ea polasetiki bakeng sa bareki ...